- Top Page

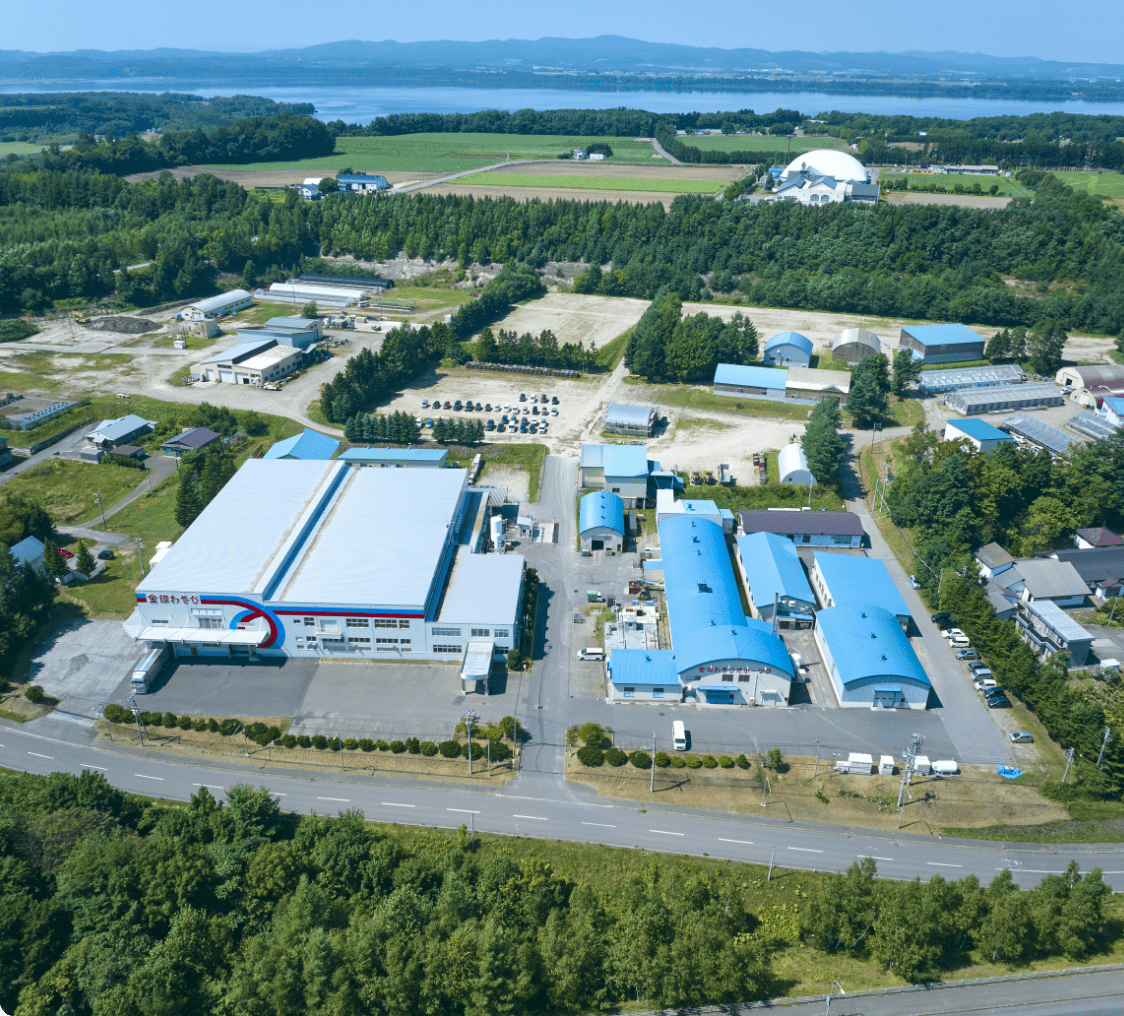

- Industry-Leading Production Facilities

Industry-Leading

Production Facilities

Production Facilities

At KINJIRUSHI's production facilities, we implement various innovations at each stage of the production line to ensure that the fresh, vibrant aroma and spiciness of wasabi reach our customers' tables with minimal loss.

Removing Even the Smallest

Foreign Particles with

X-Ray Detection and Metal Detectors

-

Because our products are something that people consume, KINJIRUSHI remains dedicated to ensuring their safety. Our product inspections use the latest detection equipment, allowing us to identify even the tiniest foreign particles—smaller than iron sand—that are impossible to detect with the human eye. We are committed to ensuring our customers can enjoy our products with confidence.

-

Final inspection by human eyes

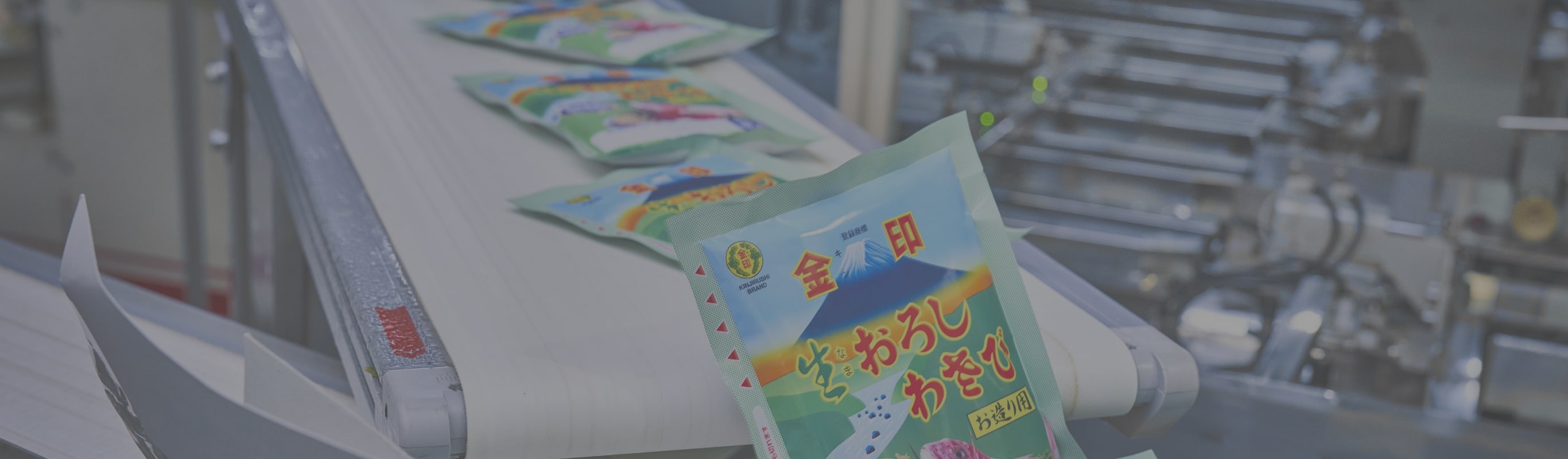

A Production Line Designed

to Preserve Aroma and Spiciness

Innovations at Every Stage

of the Production Line

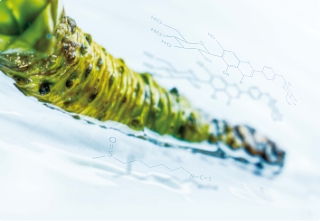

Due to its natural properties, wasabi undergoes an enzymatic reaction the moment it is grated, causing its aroma and spiciness to evaporate. At KINJIRUSHI's production facilities, we implement various innovations at each stage of the production line to ensure that the fresh, vibrant aroma and spiciness of wasabi reach our customers' tables with minimal loss.

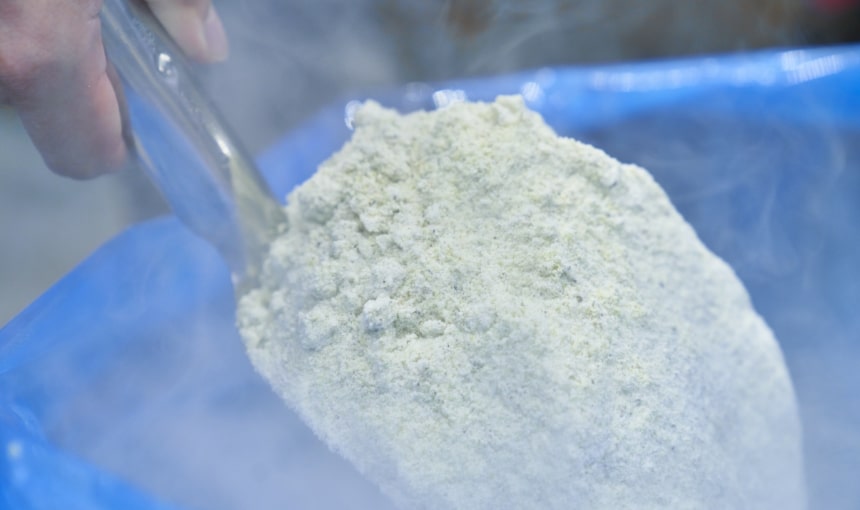

-196 °C Ultracold Grating

Delivers our Freshly Grated Sensation

-

To deliver the fresh aroma and spiciness of just-grated wasabi, we developed KINJIRUSHI's exclusive Ultracold Grating method, in which wasabi is grated at -196 °C. This method locks in the wasabi's aroma and spiciness through freezing. By delivering it to customers in its frozen state, they can enjoy the freshly grated flavor as the wasabi thaws.

-

A Production Line Designed

to Maintain Low Temperatures

The wasabi grated at ultra-low temperatures is immediately packed under cold conditions to prevent the enzymatic reaction that causes its aroma and spiciness to dissipate. It is then stored in large freezing facilities and delivered to customers while still frozen.

Striving for Industry-Leading

Safety Standards

-

We implement comprehensive food defense measures, including biometric entry systems for factory access control, foreign substance management, and 360-degree surveillance cameras for thorough cause investigation in case of emergencies, ensuring a safe and secure production environment for our customers.

-

Our Commitment

to Our Products

Delivering Safe and

Reliable Products

-

Our Mission is to Deliver

Truly Delicious and Safe ProductsIn 1973, KINJIRUSHI Wasabi became the first in the industry to successfully develop fresh grated wasabi using fresh wasabi, which was previously considered too difficult to process. We have continued providing this product to our customers ever since. Before developing this fresh grated wasabi, we produced powdered and paste wasabi using horseradish as the main ingredient. However, these products could not fully replicate the fresh aroma and spiciness of real wasabi. Wasabi is an extremely delicate fresh spice. Upon grating, an enzymatic reaction occurs, producing its signature refreshing aroma and spiciness, which quickly evaporate. Therefore, simply grating and using fresh wasabi as-is results in a product with diminished aroma and spiciness.

To develop truly delicious wasabi products, our research institute focused on storage technology to maintain ingredient freshness and methods to suppress the enzymatic reactions responsible for aroma and spiciness, ultimately making fresh grated wasabi possible.

Furthermore, to ensure the delivery of safe and reliable products, we have implemented various measures, including a traceability system for raw materials, metal detectors and X-ray inspection systems to prevent foreign contamination, and an entry-exit management system for our factories. We will continue to deliver even more delicious, safe, and reliable products in the future. -

President

Ryoichi Ishikawa