- Top Page

- Quality Control Efforts

Quality Control Efforts

Wasabi is handled like a fresh food,

making it a very delicate ingredient that cannot be sterilized through heating.

To ensure safe products for our customers,

we have established various inspection devices and specialist teams

to conduct thorough quality checks.

Industry-Leading Quality Control System

in the Spice Industry

-

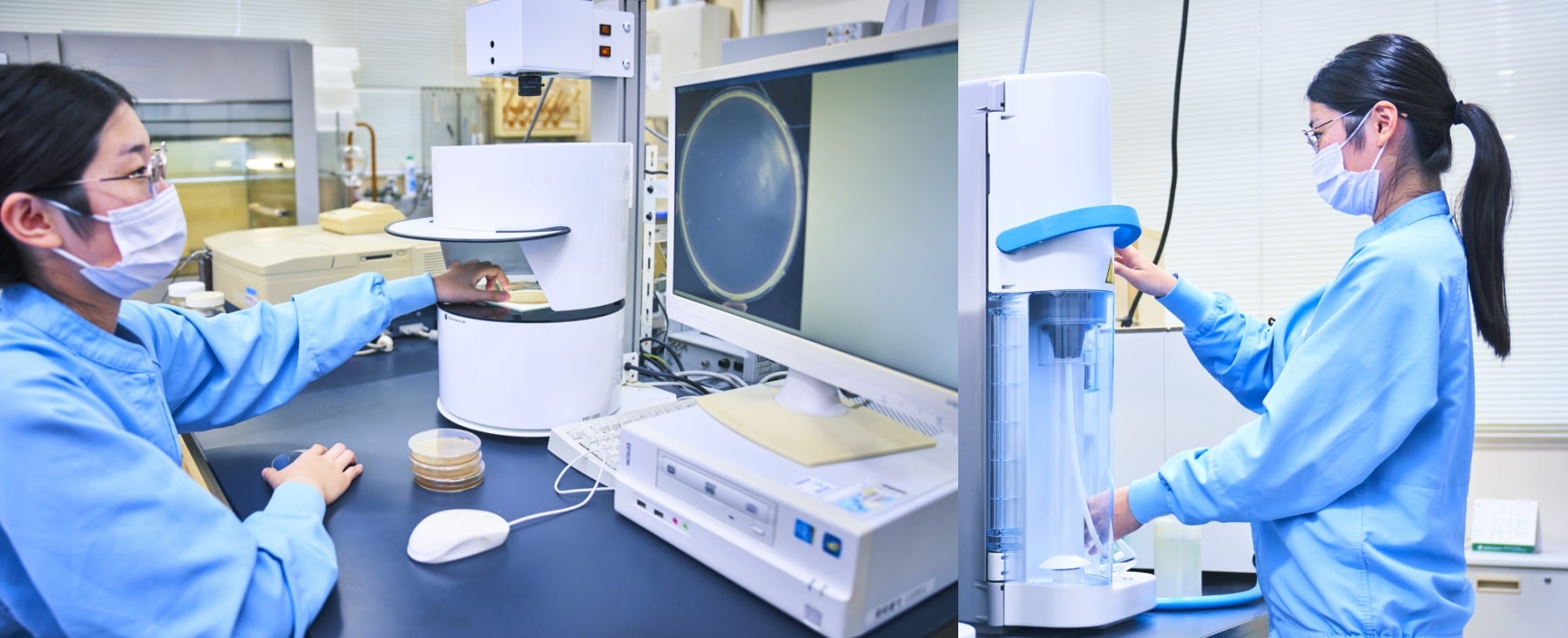

To ensure safe products for our customers, KINJIRUSHI's Quality Control Department has established various inspection devices and specialist teams to conduct thorough quality checks.

Examples of Inspection Items

· Microbial inspection (general bacteria, E. coli)

· pH value inspection

· Inspection of spiciness content

· Color value inspection

· Salt content inspection

· Moisture content inspection

· Aroma inspection (for aroma series products)

· Sensory evaluation -

KINJIRUSHI's Quality Checks

Extend to Incoming Raw Materials

-

1. Inspection of Incoming Raw Materials

Inspectors sample wasabi raw materials sent by producers and check whether they are free from microbial contamination and if there are no issues with color or condition. If any raw material is determined to have quality issues at this stage, we immediately halt the incoming shipment and have a system in place to trace whether other problematic materials have also been delivered.

-

-

2. Sanitation and Quality Checks in the Factory

Sanitation inspectors conduct daily patrols to confirm multiple checkpoints, such as whether the factory is kept clean, if manufacturing machines are free of contamination, and whether workers are handling products correctly, ensuring product safety. Additionally, products undergoing manufacturing are inspected in the adjacent quality control room, and if any irregularities are found, staff from the Quality Control Department promptly investigate the cause and resolve the issue.

-

-

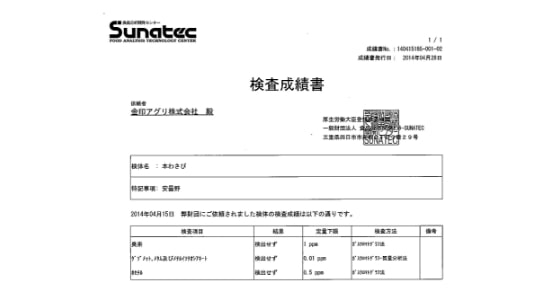

3. Inspection of Finished Products

Only products that pass inspections at every stage—from raw material arrival to finished product—are shipped. We also test whether product quality is maintained within the stated shelf life and storage conditions, as well as how quality changes if those conditions are exceeded.

-

-

Strict Raw Material

Quality StandardsTo produce high-quality and delicious wasabi products, KINJIRUSHI has established strict raw material quality standards.

Examples of Inspection Items

· Microbial inspection (general bacteria, E. coli)

· Wasabi size and color

· Residual pesticide inspection

· Handling of raw material processing machinery

· Processing environment (over 70 items) -

Raw materials that meet quality standards

Traceability System

In case of any defect, we thoroughly manage all stages—from raw material cultivation information to sub-ingredient and food additive usage, storage, and distribution—so the cause can be quickly identified and addressed. The three domestic factories under KINJIRUSHI Wasabi Co., Ltd. have all acquired FSSC22000 certification under the Global Food Safety Initiative (GFSI).

-

Product Quality is

Created in the FactoryIn 2017, we obtained certification under the ISO22000 series, the internation standard for food safety, and in 2018, our three factories received FSSC22000 certification under the Global Food Safety Initiative (GFSI), further reinforcing safety measures.

-

FSSC22000 certification